Words Lester Perry

Images Play Creative

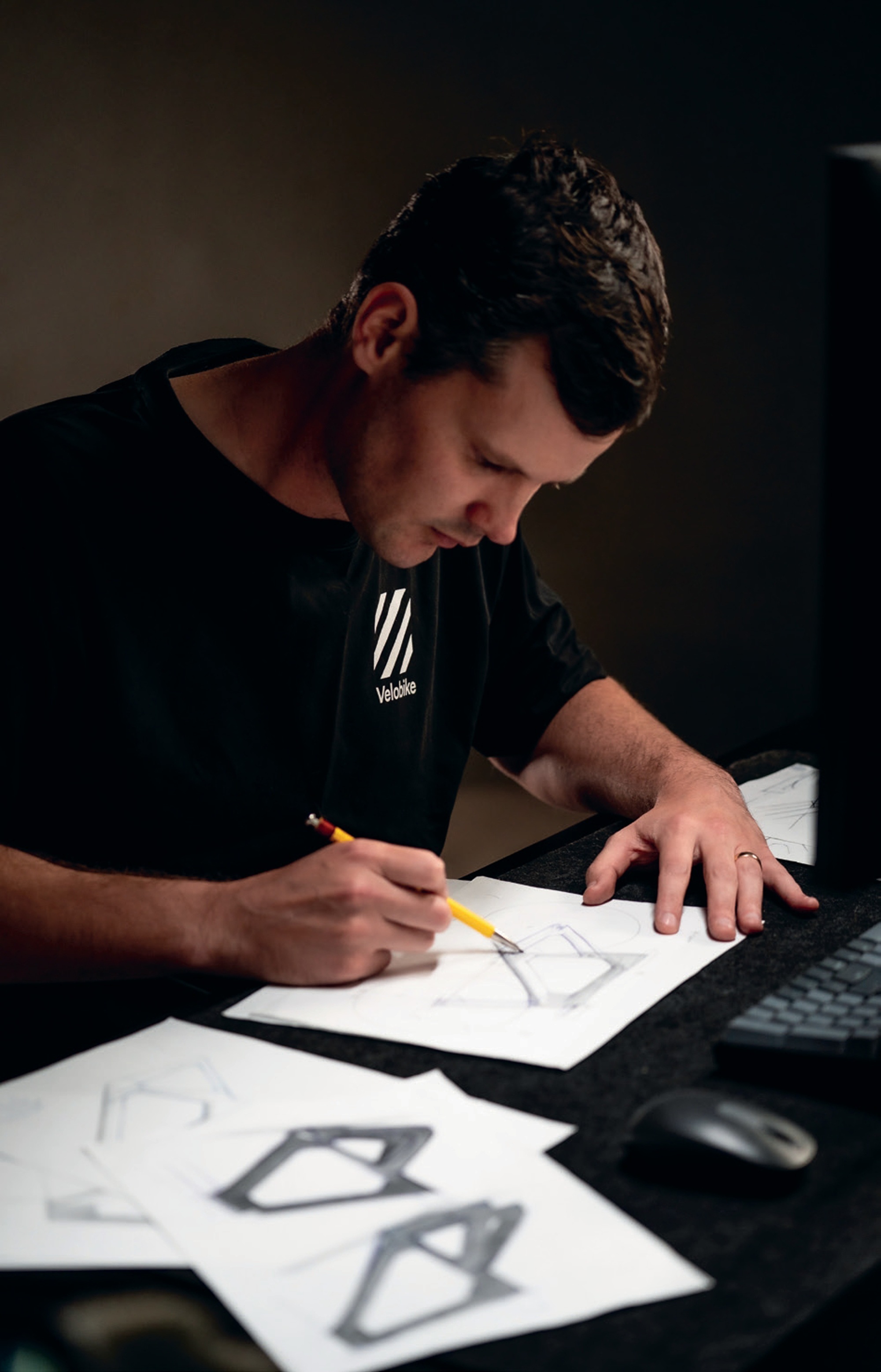

Back in 2020, when we last caught up with Glenn Catchpole of Velobike Innovation, he was operating out of Inglewood in Taranaki, as a true startup.

The brand had been a side gig for Glenn, before packing in his day job to operate from a door propped up to make a desk in his garage. Soon after, to expand on the momentum he’d built with the brand at the Tokyo Olympics, Glenn moved to a new home at NZ’s track cycling epicentre, Cambridge.

Launching in 2018, the brand has become synonymous with supplying high-performance track-racing parts, taking learnings from working with the highest tier of elite athletes, applying them to precision parts designed from the ground up, and releasing them publicly for use by riders at all levels around the globe.

Working from a rented house for six months while a new commercial premises was constructed on the fringes of Cambridge, Glenn and his wife, Valerie, began work towards 2024 and the Paris Olympic cycle.

With their new premises complete, Velobike, as we now know it, began.

“When we moved in here, we were like, whoa, we’ve got way too much space. But we quickly managed to fill it up. A lot of it has been about making the most use of the space and, as we grow, getting more efficient with it.”

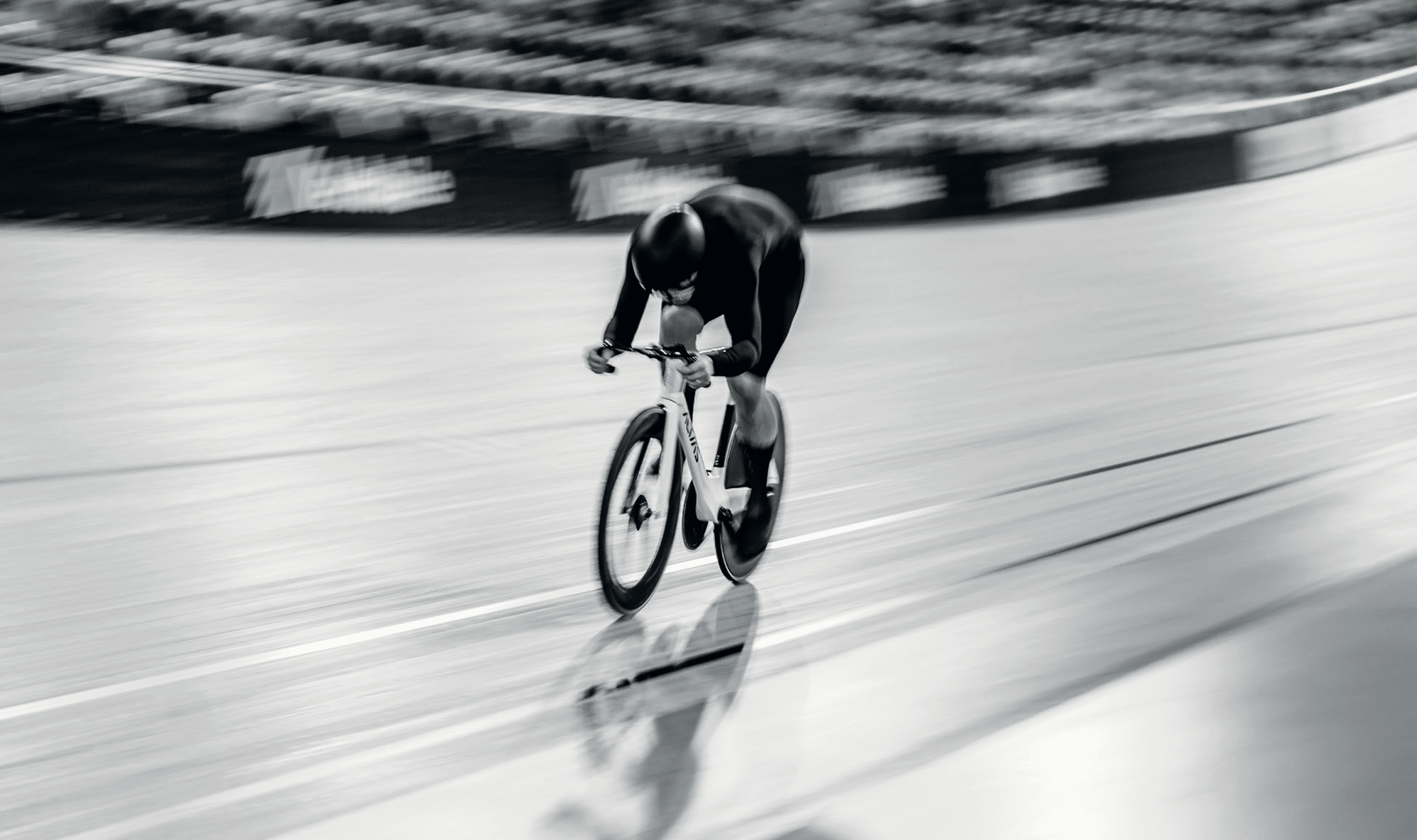

Working closely as a supplier to federations in numerous countries, Velobike supplies parts that have so far contributed to some 43 medals, a tally far above what one would expect from a small brand based down in the bottom corner of the world.

“There’s a supplier relationship where they’ll just buy stuff from us because it solves their needs. But then, what we’re actively trying to focus on more, and it’s probably happening a bit more this Olympic cycle, towards Los Angeles, because we’ve got a bit more of a reputation so they’re (national federations) coming to us and going, hey, we’ve got a problem, we want to optimise a product to solve this, specifically for our needs. And that’s where we’ve really tried to direct the business – toward more high-value, niche problem-solving for the federations. Because that trickles down into the wider community.”

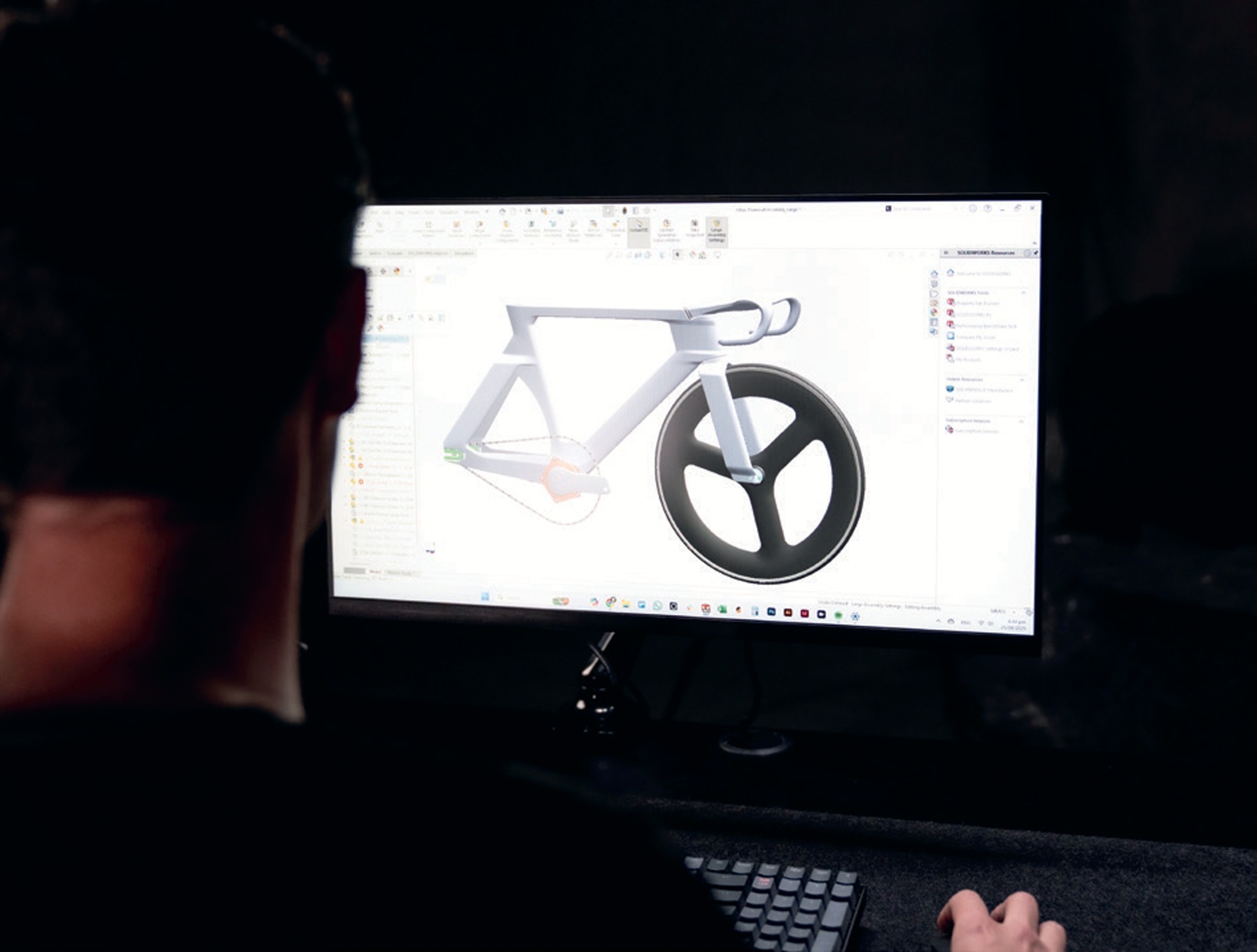

Their Cambridge move not only added credibility and proved their commitment to what they do, but also allowed them to bolster their team, enabling growth and efficiency. Now a crew of six, the Velobike team handles the nuts-and-bolts of running the business so Glenn can focus on what he does best: dreaming big and innovating. Wayne oversees the company’s retail operations. Valerie handles logistics and admin, Julia is a designer, and Tait and Joel (the only part-timer) handle order fulfilment. The team is tight but capable, helping Velobike to punch well above its weight.

With the aim of peak performance, many federations have been creating bikes optimised for a given rider, and while this works in one sense, these “super bikes” are never really commercially viable. They technically have to be available for purchase to be UCI legal, but with a high price tag and long delivery times, they’re out of reach for a retail buyer, so it’s easy to skirt this rule. Custom frames with custom cockpits, forks, and wheels that may be fast for a specific rider but aren’t for another, mean these bikes and the budgets involved, are not accessible to many federations – and certainly not to independent riders.

Glenn is often looking for gaps or grey areas between the UCI rules, where a product could help a rider gain an edge, aiming to design items that will help the top tier of the sport be faster. Often, all they need is a 100th of a second to win or set a record, so every optimisation counts. All Velobike components are designed around industry standards, ensuring nothing is intended solely for a specific bike, and keeping them accessible and relevant to the masses.

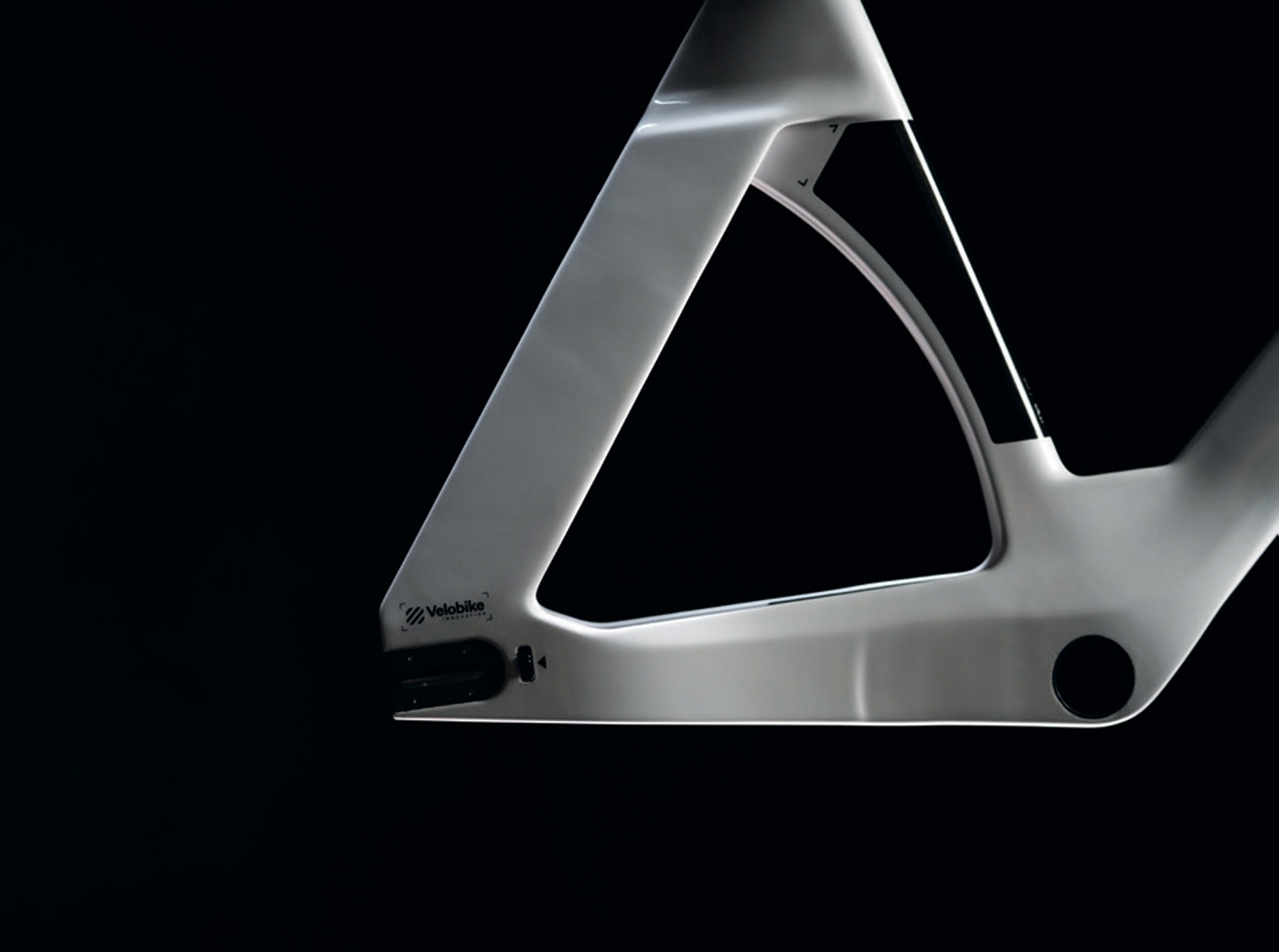

The Velobike range has grown over the years, beginning with chainrings and now encompassing specialist parts across a whole track bike, from cogs to handlebars and everything in between. Although they’ve had an almost complete range, there’s been one item that Glenn has been patiently developing to bring the selection of components together: an in- house-developed track-racing frame that adheres to his modular design philosophy, taking his learnings from the last eight years and bringing them to life.

“The whole bike is based around a system. How do you not just make a frame, but make a bike and rider system that can be optimised through modularity for the different race contexts or different athletes?”

Glenn describes his approach to the design of the Altias as a constant search for balance: a tightrope walk between modularity and optimisation. On one side is a modular design that’s adaptable, configurable, and built to suit a range of athletes. These bikes can adapt in height, angle, and shape, with parts that swap out easily to fit different riders or setups

On the other side lies pure optimisation, the realm of high-end, high-value, one-piece, purpose-built components designed for a single athlete. Although costly and complex, they deliver maximum performance: lighter, stiffer, stronger, and more aerodynamic. This is the realm of very few well-funded nations. The trade-off, of course, is flexibility. What’s perfect for one rider might be useless for another.

Finding the sweet spot between those two extremes is the real art, according to Glenn. It’s not just an engineering decision but a business one. How do Velobike deliver precision performance while still making equipment accessible and adaptable to more athletes?

When hundredths of a second can decide everything, the modular approach only goes so far. At some point, performance requires pure optimisation. That push- pull between adaptability and precision became the foundation for the Altias’ design. Glenn made a deliberate effort to strike a balance between the two.

The result is a frame that, like Velobike components, avoids proprietary systems. The steerer tube uses a standard inch and an eighth diameter, allowing riders to bolt on any conventional stem. The team is developing components that will further enhance speed without being proprietary: semi- integrated cockpits will refine aerodynamics and stiffness without locking riders into a single configuration like a one-piece solution would.It’s a philosophy that sets them apart from many frame manufacturers, who focus solely on the frame of the bike and leave the supporting components to the wider industry. That approach, Glenn argues, often compromises overall system performance.

Benchmarking against the leading frames in the sport and partnering with proven, experienced manufacturers ensures that the build quality, stiffness, and weight are top-tier. When this engineering prowess is combined with Glenn’s aerodynamic optimisations, the Altias surpasses the bikes it’s benchmarked against.

Looking ahead, the Altias’ design will allow national teams to further customise the setup, particularly at the front end. For example, in the Flying 200 qualification rounds, riders typically use a disc front wheel, prioritising straight-line speed. But in the match sprints where the real action happens, riders may switch to a spoked wheel for snappier handling. The plan is to offer different forks to meet those race-day demands as airflow reacts differently across wheel, fork, and rider combinations. This adaptability will allow fine-tuning for each event or rider without abandoning the frame’s underlying modularity.

As framesets began to arrive at their Cambridge facility, a scramble for more space led to a redesign of their main office within the warehouse. The top of the office roof now serves as a space for inspecting, packing, and storing Altias framesets before they’re shipped around the globe. In true Kiwi DIY fashion, frames destined for European customers will be shipped from Velobike’s facilities in the Netherlands: Valerie’s parent’s garage!

Leading toward Los Angeles 2028, work with federations is well underway. On the day I visited their offices, 3D printers were buzzing, creating prototype parts, and Glenn told me of ideas that could rewrite track racing as we know it. The future is bright for Velobike, and as they have done in past Olympics, I’m positive we’ll see record performances not only on their components but possibly now on the Altias, a frame developed just a stone’s throw from cows grazing in paddocks on the edge of Cambridge.